What Is 430 Stainless Steel?

430 stainless steel is an economical and practical ferritic stainless steel. Due to its excellent corrosion resistance, superior processing performance and relatively low cost, it is widely used in architectural decoration, household appliances, kitchenware and industrial equipment, etc. Compared with high-nickel austenitic stainless steels such as 304 and 316, 430 stainless steel contains no nickel and is more competitive in price. At the same time, it can still provide sufficient corrosion resistance and mechanical strength, making it an ideal choice for many industries.

The Chemical Composition Of 430 Stainless Steel

430 stainless steel is a ferritic stainless steel. Its core component is mainly chromium (Cr), without nickel (Ni), so it has a relatively low cost, but still possesses a certain degree of corrosion resistance..The high chromium content (16%-18%) of 30 stainless steel enables it to perform well in dry environments and weak corrosive media. However, due to the absence of nickel, its resistance to acid and chloride ion corrosion is inferior to that of 304 or 316 stainless steel.

| Element | content(%) | Function |

| Cr | 16.00 – 18.00 | Form a chromium oxide passivation film to provide basic corrosion resistance |

| C | ≤0.12 | It affects hardness and weldability, and low-carbon reduces the risk of intergranular corrosion |

| Si | ≤0.75 – 1.00 | Enhance antioxidant properties |

| Mn | ≤1.00 | Enhance strength and processing performance |

| P | ≤0.040 | Increase strength, but excessive use will reduce toughness |

| S | ≤0.030 | It improves cutting performance, but excessive use affects weldability |

| Ni | ≤0.60 | Trace amounts of nickel can enhance corrosion resistance, but it is not the main component |

The Main Characteristics Of 430 Stainless Steel

1. Good corrosion resistance (suitable for dry and weakly corrosive environments)

- It performs well in environments such as the atmosphere, water vapor, and organic acids (such as acetic acid).

- It has good corrosion resistance in oxidizing acids (such as dilute nitric acid) and is suitable for chemical equipment .

- Not suitable for high-chloride ion environments (such as seawater), long-term exposure may cause rust.

2. Excellent processing performance

- It is easy to cut, stamp and weld, and is suitable for processing complex shapes.

- Strength and hardness can be enhanced through cold working hardening.

- When welding, pay attention to the issue of 475℃ embrittlement and avoid staying at high temperatures for a long time.

3. Magnetism (ferrite structure)

- 430 stainless steel has strong magnetism and can be used in electromagnetic equipment or applications that require magnetic adsorption.

4. Lower coefficient of thermal expansion

- Compared with austenitic stainless steel (such as 304), 430 stainless steel has a lower coefficient of thermal expansion, and its dimensions are more stable in high-temperature environments, making it suitable for heat exchangers, stoves, etc.

5. Economy (nickel excluded, low cost)

- Because it does not contain the expensive nickel (Ni), the price of 430 stainless steel is 30% to 50% lower than that of 304 stainless steel, making it suitable for budget-sensitive applications.

The Main Application Of 430 Stainless Steel

430 stainless steel, with its high cost performance, easy processing and oxidation resistance, is widely used in the following industries:

1.Architecture and decoration

- Building exterior walls, interior decorative panels, door and window frames, elevator decorations.

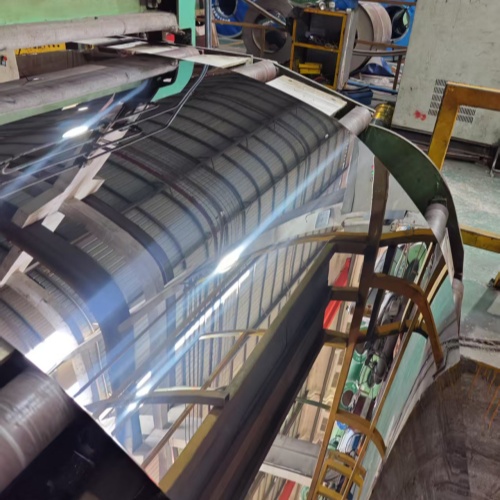

- The surface can be processed into various effects such as matte (1D), brushed (HL), and mirror (BA), enhancing the aesthetic appeal.

2. Household appliances and kitchenware

- Refrigerator panel, microwave oven shell, washing machine inner drum.

- Kitchen knives, cookware and tableware (please note that long-term contact with acidic foods may affect corrosion resistance).

3. Automobiles and industrial components

- Automobile exhaust pipes, decorative strips (with good high-temperature resistance).

- Fuel nozzles, stove components (resistant to oxidation environments below 900℃.

4. Chemical and food equipment

- Dilute nitric acid (HNO₃) storage tank, heat exchanger (suitable for weakly acidic environment).

- Food processing equipment (must ensure smooth surface and meet hygiene standards).

Conclusion

430 stainless steel is an economical, practical and easy-to-process ferritic stainless steel, especially suitable for applications with limited budgets but still requiring certain corrosion resistance. Although its corrosion resistance is not as good as that of 304 or 316 stainless steel, it still has extensive application value in fields such as architectural decoration, home appliances, automotive parts, and kitchenware.