No.1 vs 2B Finish: Choosing the Right Stainless Steel for Heavy-Duty Use

NO.1 stainless steel and 2B stainless steel are two commonly used stainless steel materials, with its excellent corrosion and strength, widely used in various fields. However, in different circumstances, we need to choose different products. This article is mainly an in-depth analysis of the difference between NO.1 and 2B stainless steel, so as to give better recommendations for customers who use the materials in high-load environments.

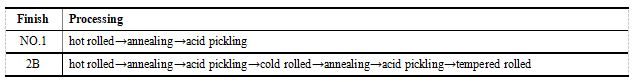

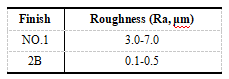

Different Processing and roughness

NO.1 Surface: After hot rolling, annealing, pickling and other processes, the surface is silver-white, with obvious rolling texture, and relatively high roughness. This natural rough surface provides a better coefficient of friction, making it less likely to slip under high load environments, and is more suitable for occasions where grip or friction is required.

2B Surface: Based on the NO.1 surface, after cold rolling, annealing, pickling and tempering rolling, the surface is smoother and smoother, with lower roughness, showing a matte effect. Although the appearance is more beautiful, its smooth surface may cause insufficient friction in high load environments, affecting performance.

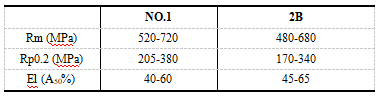

Mechanical Property

NO.1 Surface: Due to the processing technology, the NO.1 surface retains part of the rolling stress, and its mechanical strength is slightly higher than that of the 2B surface. This higher strength allows it to withstand greater pressure and impact, and is more suitable for high load and high intensity application scenarios.

2B surface: After tempering and rolling, the internal structure of the 2B surface is more uniform. Although the strength is slightly lower than NO.1, its comprehensive mechanical properties are better and its toughness is better. However, in high load environments, its lower strength may be a limiting factor.

Application comparison

NO.1 surface: With their excellent mechanical strength and rough surfaces, NO.1 surfaces are ideal for harsh environments.

- 1.Building structural parts: Withstand wind and rain erosion and gravity loads, NO.1 surface provides stronger support and durability.

- 2.Industrial equipment frame: withstand mechanical vibration and shock, NO.1 surface ensures stable operation of equipment.

- 3.Heavy machinery parts: Withstand high loads and wear, NO.1 surface extends component life.

2B surface: Suitable for applications requiring high surface finish and corrosion resistance

- 1.Food processing equipment

- 2.Medical device

- 3.Chemical equipment

- 4.Decoration

Conclusion

The surfaces of NO.1 and 2B have their own advantages, but under high load environments, the surface of NO.1 exhibits better performance with its higher mechanical strength and roughness, making it the best choice in harsh environments.